Our Designs

COMPUTER CONTROLS

Each microcontroller system is designed in house by Economy Controls. We design our own circuit cards, and program all microprocessors ourselves, giving us unlimited flexibility to meet customer requirements. Each completed controller card is fitted with plug in connectors for easy replacement.

Having complete control over each component in our electronics, we are able to diagnose and repair damaged operating cards, rather than replacing them. These two features add up to ease of repair and customer savings.

We are not limited to our own controls. We can use any controls preferred by customers.

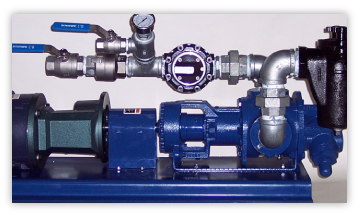

BLENDING SYSTEMS

Inline blending of oils with positive displacement meters and variable speed pumps is a precise closed loop design, which offers smoother, more efficient, and more accurate operations than control valve systems. Blend ratios are on target at start up and as fuel demand rapidly changes. Control valves independent of pumps can be slow to respond and control in higher viscosity applications, and many designs require by pass lines, which add expense and consume more energy.

Inline blending of lighter liquids, such as ethanol, are suited for turbine pumps and control valve systems. Care must be taken in sizing “static head” systems to assure proper pressure differential to achieve 100% of specified flow.

In-tank metered blending works well only if the products are homogeneous and mix well, or if in-tank mixers are used, and the product does not layer in storage. Otherwise, product quality is effected.

Blending ratios of 0 – 100% of multiple liquids requires independent control of each liquid.

With over 40 years of fluid transfer design experience, Economy Controls can provide either the components or a complete “turn key” system, for any blending project.